Die Casting in Malaysia: Advancing Know-how for a Competitive Business

Die Casting in Malaysia: Advancing Know-how for a Competitive Business

Blog Article

Die-casting in Malaysia is now a significant industry, playing a crucial role for the nation's manufacturing and industrial sectors. The process of injecting molten metal into a mold to produce precise metal parts has become essential for industries such as electronic, aerospace, automotive and other consumer goods. Malaysia is now an international hub for top-quality die casting because of its highly skilled workforce, state-of-the-art technology, and strategic location in the global supply chain. Many international companies have set establishments in Malaysia, leveraging the country's expertise in metal casting and engineering. Demand for components made of die-cast is growing as companies seek out cost-effective, durable, and precise metal parts to make their products. As technology advances Die-casting in Malaysia will likely to grow further and adopt new technologies that will improve efficiency and increase sustainability.

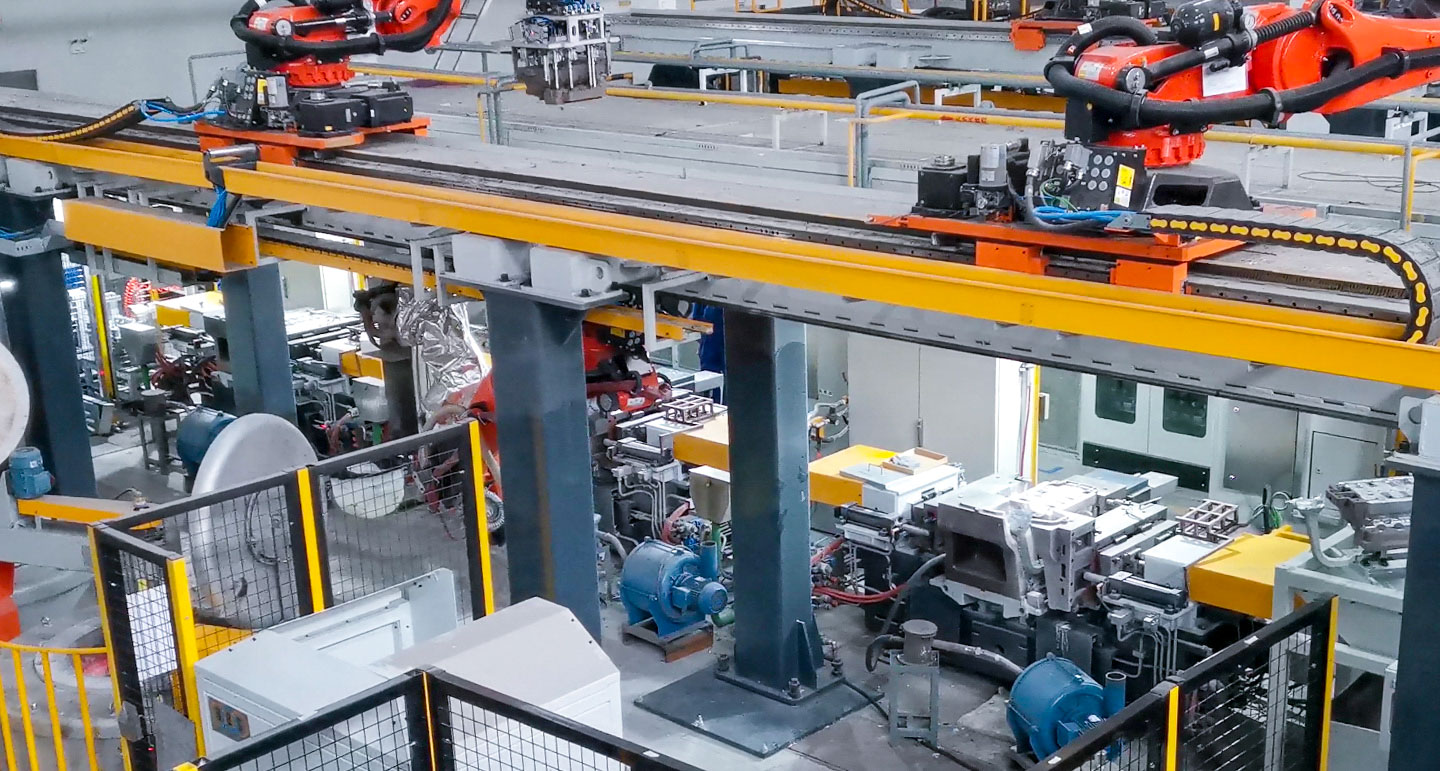

The automotive industry is one of the biggest users of die-cast parts in Malaysia because manufacturers depend on the process for robust and light-weight vehicle components. Transmission cases, engine blocks as well as structural parts typically are made of magnesium and aluminum alloys because of their superior strength-to-weight ratio and resistance to corrosion. With the shift towards electric vehicles , the demand for precise die-cast parts has grown as the manufacturers concentrate on improving efficiency and reducing the overall weight of vehicles. There are many Malaysian die-casting firms have formed partnerships with global automotive brands providing essential components that meet stringent international standards for quality. Malaysia's contribution to the automotive industry is further strengthened by the investment into research and development, which improve the production methods and make sure that the manufacturers stay on top of the game in an ever-changing market. As automation is integrated into and intelligent manufacturing Die-casting is set to become even more productive and ingenious over the next few years.

Die casting is also integral for the electronics and telecommunications industries of Malaysia where accuracy and reliability are essential. The country is a major exporter of electronic parts, providing global companies with top-quality heat sinks, metal enclosures, and connectors. The ability of die casting to produce complex shapes that are precise in their tolerance makes it ideal for manufacturing these parts, which ensures they can be seamlessly integrated into various electronic gadgets. There are many Malaysian die-casting companies work closely with companies in the field of technology to design specific solutions to smartphones, laptops Data centers, laptops, and other telecommunications equipment. As the growth continues in the digital economy, the demand for die-casting components that are advanced is predicted to grow. Businesses are focused on increasing insulation properties, electrical conductivity and light weight properties to enhance the performance of electronic devices. Automation and smart manufacturing techniques can further improve efficiency in the production of high-precision metal parts.

Sustainability has become an important focus for Malaysia's die-casting industry and companies are actively adopting eco-friendly manufacturing techniques. Recycling and reusing metal materials, particularly zinc and aluminum, are now common practice in die casting, reducing the amount of waste produced and preserving resources. Many manufacturers have also adopted efficient casting and melting techniques that use less energy to minimize carbon emissions and the overall consumption of energy. The shift toward environmentally sustainable manufacturing has spurred industries to look into cleaner casting techniques, such as low-pressure die casting and gravity die casting. These techniques create high-quality products with less loss. Coatings and surface treatments that improve the longevity and corrosion resistance of the components that are die-cast are being created using green components. With industries around the world pushing towards greener supply chains Malaysian die-casting businesses are positioning themselves as leaders in environmentally friendly metal casting, ensuring long-term competitiveness in the world market. To find more information kindly go to https://www.senadiecasting.com.my/

The growth of die casting in Malaysia is further supported through advancements in mold design and manufacturing that play an essential part in the production of high-quality parts. Mold-making and precision tooling techniques have evolved to improve the quality of products, their durability as well as efficiency of production. By integrating computer-aided design, and computers-aided manufacturing software, companies are able to create molds that are extremely complex with tighter tolerances. Technology advancements have enabled speedier production processes, while lowering cost and increasing overall efficiency. The use of simulation software can further improve the performance of molds by predicting defects and optimizing casting parameters. In the end, Malaysian die-casting companies are able to meet the growing needs of industries that require high performance that require consistent quality and reliability in their product.

The die-casting industry in Malaysia is poised to expand in the future as global demand for high-quality metal components continues to grow. Its location in the middle of Asia as well as its skilled workforce and strong commitment to technological advancement make it an important manufacturing center in the region. Companies that embrace automated, artificial intelligence and data-driven manufacturing processes are gaining a competitive edge, ensuring efficiency and product excellence. With increasing applications in electronic, automotive and aerospace industries Die-casting firms in Malaysia can expand their capabilities and strengthen their international presence. With sustainability becoming a primary issue, companies that implement green practices and energy-efficient technology will benefit from future growth. The development of the die-casting business in Malaysia is a testament to the nation's commitment to precision manufacturing, technological innovation, and economic progress and establishing its position as a global pioneer in the field of metal casting.